Manufacturing support, engineering judgment.

Relay Manufacturing helps teams move their designs to production with confidence. We review feasibility, align scope, and coordinate execution through trusted manufacturing resources - so outcomes are predictable, not hopeful.

What we do, and what we don’t

Relay is not a one-process shop. We start with the part, validate risk and feasibility, then execute through the right path whether it's in-house, through trusted partners, or via a warm intro when it’s outside our lane.

In-house

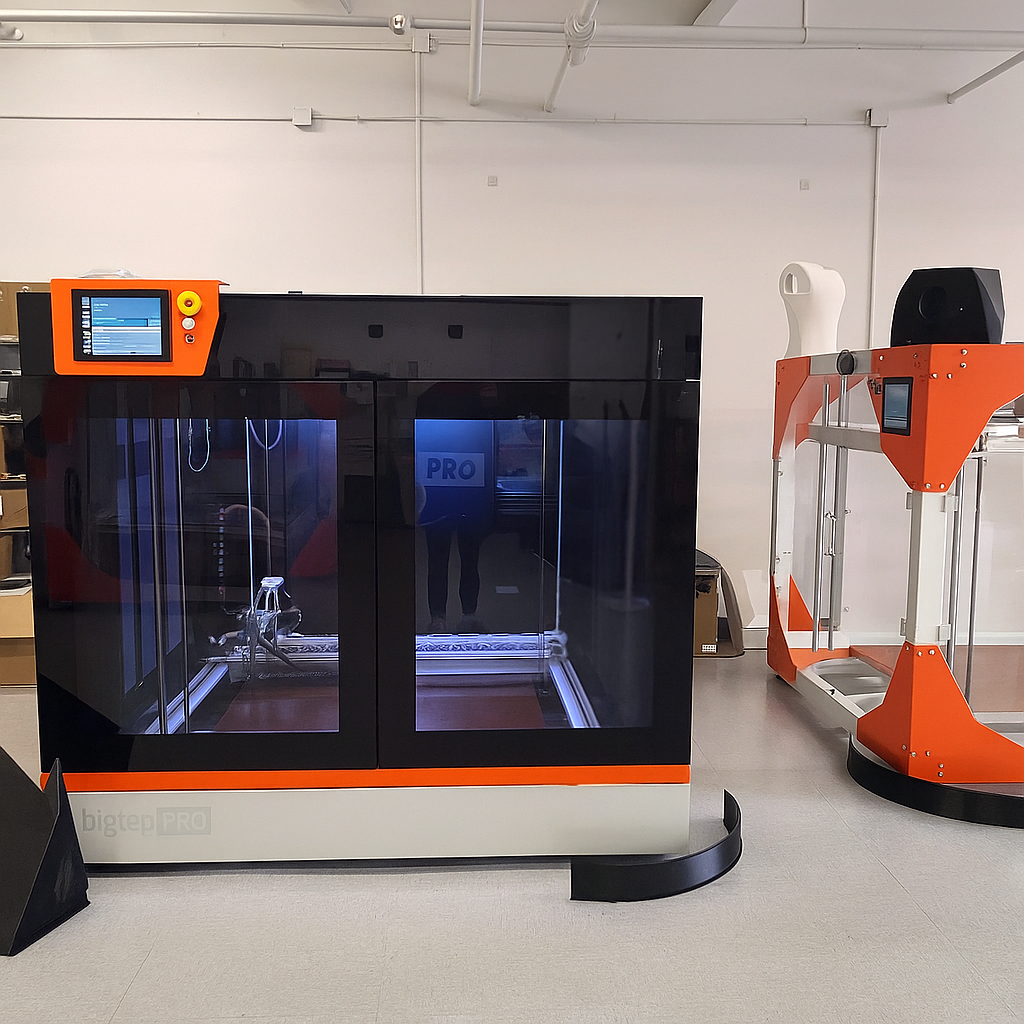

Where we own the build directly: Relay started with a focus on 3D printing and are incrementally scaling our in-house capabilities with time and customer need.

- LF-FDM (large-format thermoplastic)

- FDM (functional polymer parts)

- DLP (high-detail resin parts)

- Diode laser cutting

- CO2 laser cutting

Trusted partners

Work we’ve thoroughly vetted and can scope confidently. You still get one accountable owner who can translate your project requirements.

- CNC machining (milling / turning)

- Waterjet cutting

- Fiber laser cutting

- Forming (sheet metal, welding)

- Molding (urethane casting, injection molding)

What we’ll help you route elsewhere

If your project is outside our execution lane, we won’t fake it. We’ll tell you plainly and connect you with the right people.

- Die casting and permanent mold casting

- High-throughput stamped or progressive-die metal parts

- Certified aerospace / medical production (AS9100, ISO 13485)

- Fully automated production lines or turnkey factory builds

Everything on this page reflects processes we have real experience with and full confidence evaluating. Check back as we expand our team, partners, and experimental work - this list will keep growing.

Core capabilities

We support multiple manufacturing processes and execution paths. Each is selected based on part requirements, risk, and intended use - not convenience or machine availability.

Capabilities below are organized by what the part needs to do, not by equipment. For each, we call out typical use cases, material considerations, and how the work is executed.

3D printing

Additive manufacturing processes used for prototypes, tooling, and low-volume production where geometry, scale, or iteration speed matter.

FDM (Fused Deposition Modeling)

LF-FDM (Large-format FDM)

SLA (Stereolithography)

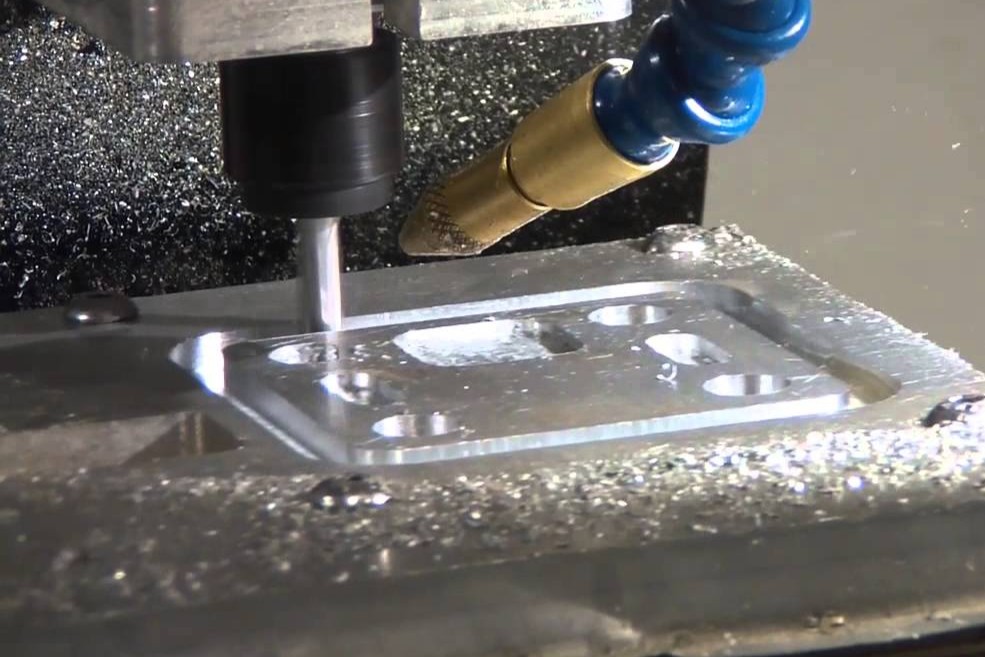

CNC machining

Precision subtractive manufacturing for tight tolerances, reliable fit, and production-grade materials — from prototypes to low-volume production.

3-axis / 5-axis milling

Turning (lathe)

Finishing & secondary ops

Forming

Sheet and plate forming for brackets, enclosures, guards, and structural parts — ideal when you want strength and repeatability without machining a block.

Press brake bending

Vacuum forming

Welding

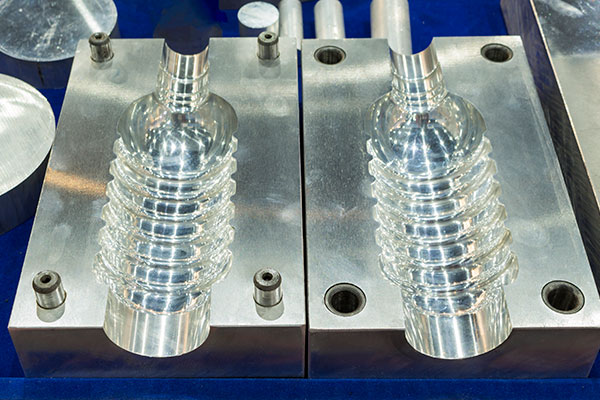

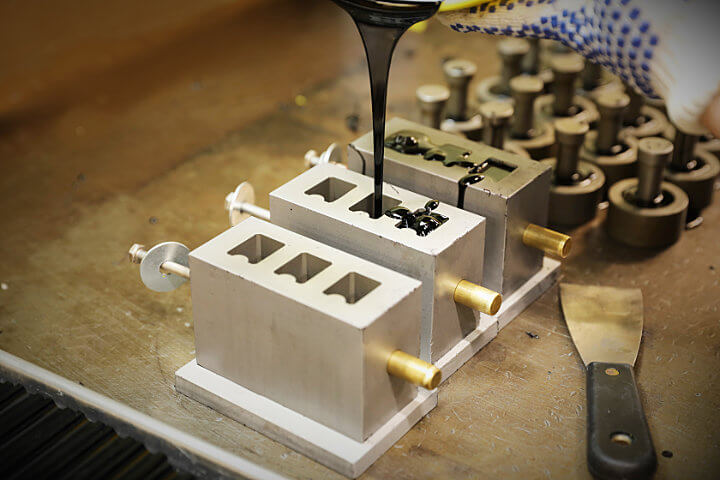

Molding

Production-friendly processes for repeatable parts at quantity — from flexible, low-commitment tooling to full injection molding when volumes justify it.

Urethane casting

Injection molding

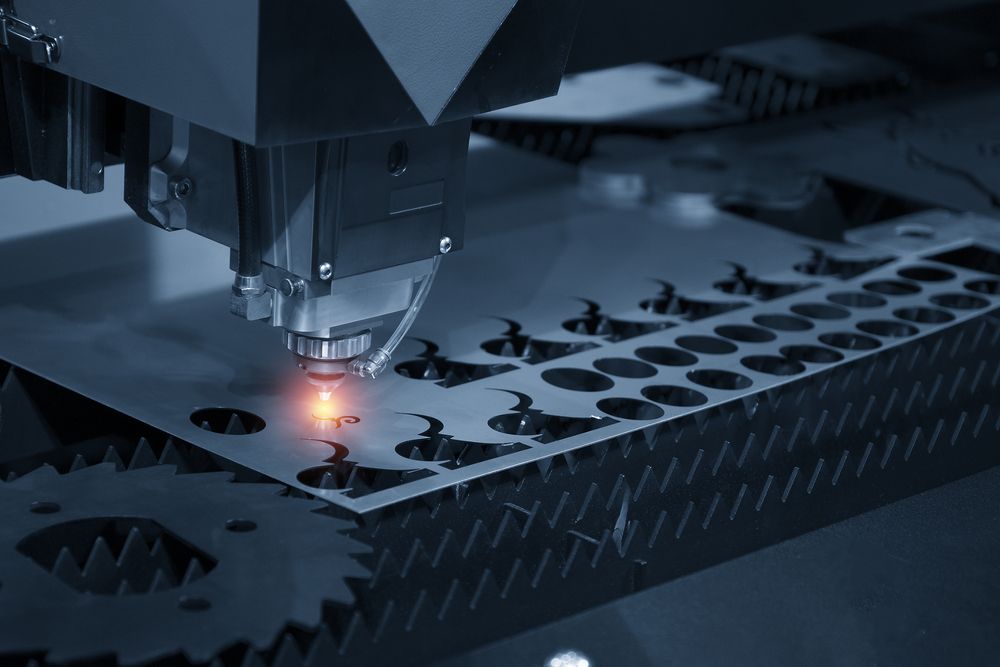

Cutting

Fast, accurate 2D profiling for brackets, panels, enclosures, and fixtures — often the most efficient path when parts are primarily planar.

Laser cutting

Waterjet

What you receive

Clear scope, predictable execution, and parts delivered ready to use — not surprises.

- Confirmed scope + assumptions before production

- Defined deliverables tied to fit + function

- One accountable owner end-to-end

- Milestone updates (not only when issues pop up)

- On-time delivery, packaged and labeled

- Clear handoff: what changed, what’s next

Is Relay a fit?

A quick gut-check to align expectations.

We’re a strong fit if you…

- Want a manufacturing plan, not just a quote

- Care about scope clarity and predictable delivery

- Have real constraints around fit, function, or materials

- Prefer one accountable owner end-to-end

- Want a process validated before spending money

We may not be a fit if you…

- Only want the lowest price or fastest checkout

- Expect instant quotes without technical review

- Prefer to manage vendors and tradeoffs internally

- Need commodity parts with minimal decision-making

- Expect “yes” answers when feasibility is unclear

Start with a technical review - not a checkout.

Submit files to get a clear fit assessment, defined scope, and next steps before anything moves forward.

No obligation. No sales pressure.