Start with a technical review.

In a world of instant quoters, Relay Manufacturing doesn’t begin with a checkout. We start by understanding your part, your constraints, and your intent. That way, the quote you receive reflects reality, not assumptions.

Why our process is intentionally different

Most manufacturing services optimize for speed at the expense of outcomes. Relay optimizes for outcomes without sacrificing speed.

We combine a thorough intake process with real engineering review so you get fewer revisions, clear scope, predictable timelines, and one accountable point of contact.

The process

Simple on purpose — with the right checkpoints to prevent surprises.

Submit your files

Upload CAD files and answer a short set of practical questions: intended use, critical dimensions, tolerances (if applicable), and timeline expectations. No configuration maze - just enough context to evaluate properly.

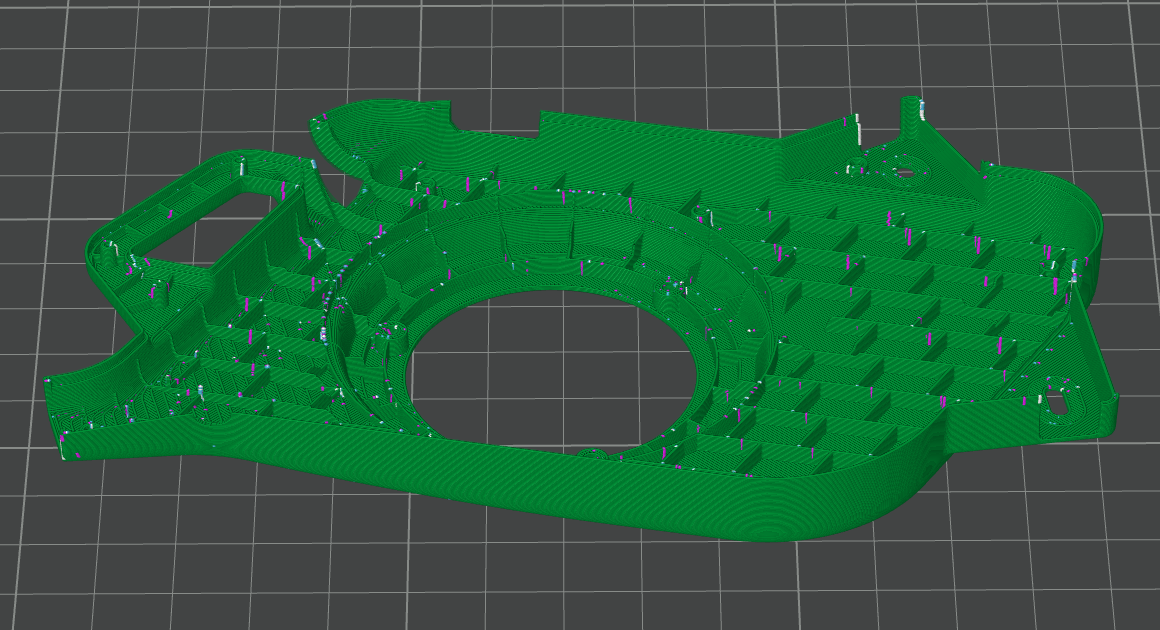

Technical review

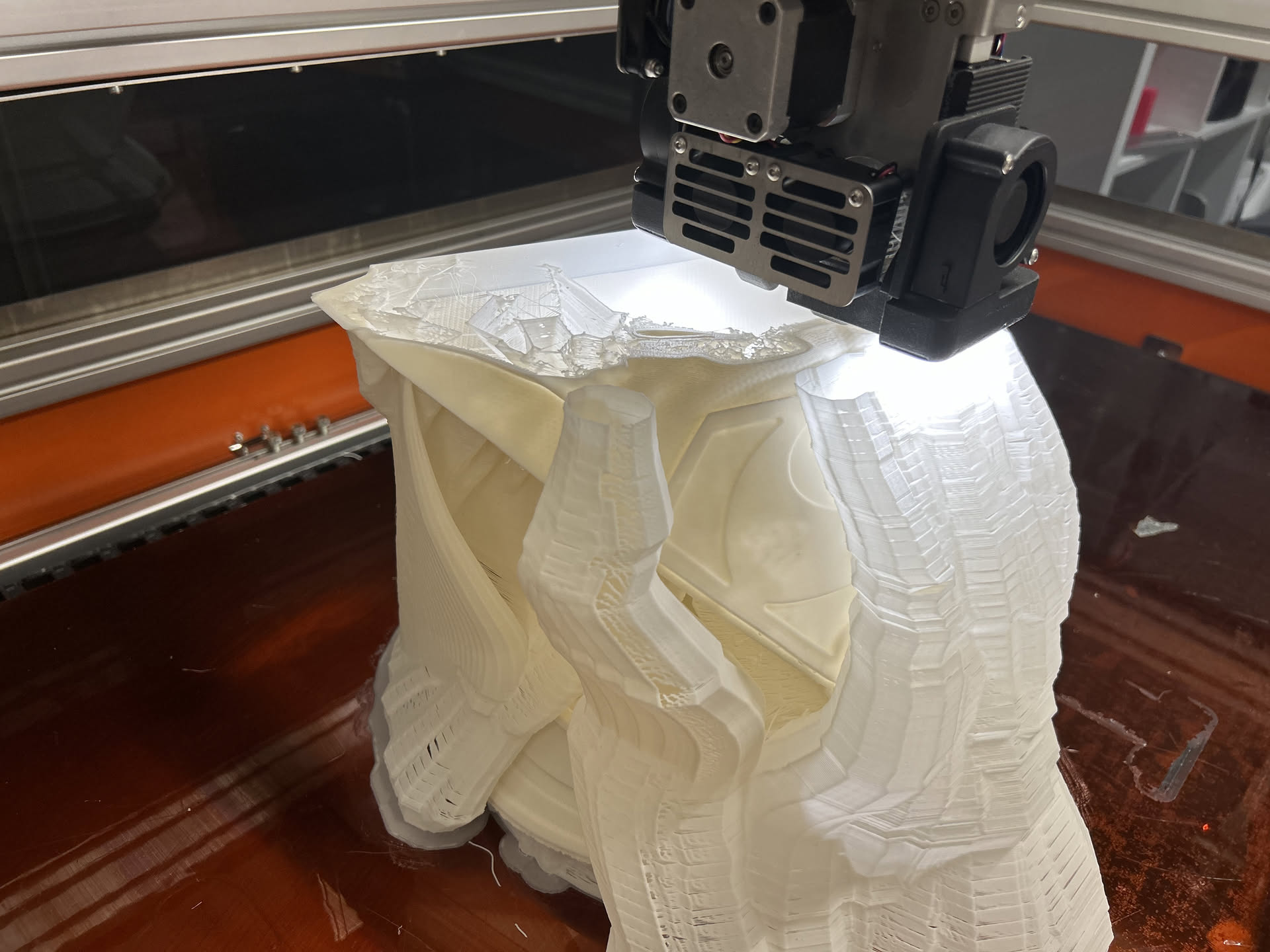

Every submission is reviewed by an engineer. We assess manufacturability, material and scale fit, risk areas (warp, support strategy, post-processing), and whether additive is actually the right solution.

Scope alignment

Before pricing, we'll reach out to align on scope as-needed to confirm assumptions, clarify deliverables, and identify tradeoffs (cost vs strength vs speed). This step prevents surprises later - for both sides.

Quoting & scheduling

Once scope is locked, we issue a clear, defensible quote with real lead times based on real capacity. If revisions are needed, they happen before production starts - not after.

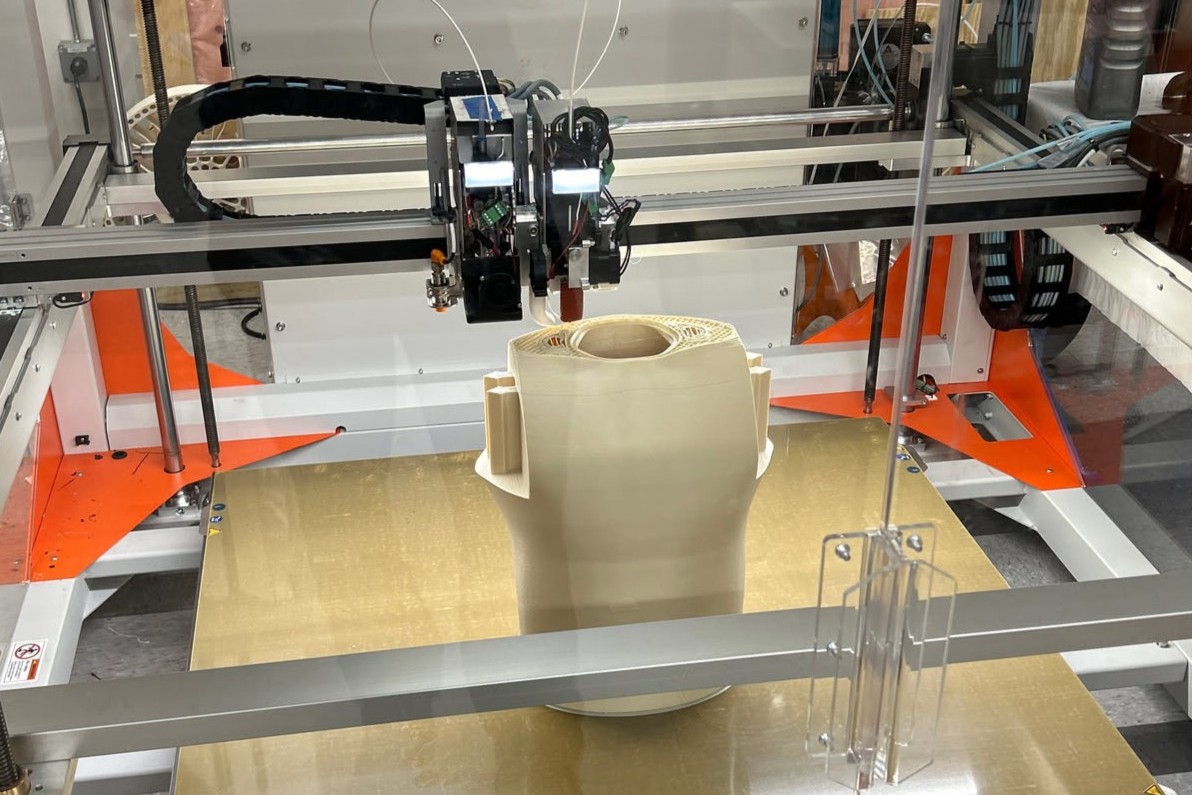

Production & oversight

We coordinate production through trusted manufacturing resources and maintain oversight throughout the build. You get a single point of contact, clear status updates, and accountability from start to finish.

Delivery & follow-up

Parts are delivered as scoped. If iteration is needed, we already understand the context - no reset needed. Many customers come back for iteration rounds, related tooling, or follow-on work.

The result

Clear scope, predictable execution, fewer surprises mid-build.

This process is a feature, not friction

Relay may not be the right fit if you only want the lowest possible price, already know exactly what machine you want, or want instant checkout without review. We’re optimized for reliability, clear communication, and engineering judgment with fewer unknowns.

clarity, predictability, and accountable execution

- Clear scope and assumptions

- Defensible pricing

- Engineering-first decisions

- One accountable owner

Start with a technical review - not a checkout.

Submit files to get a clear fit assessment, defined scope, and next steps before anything moves forward.

No obligation. No sales pressure.